Carbon fiber tube - Data sheet (EN)

Carbon Fiber Data Sheet

Carbon fiber tube - Data sheet (EN)

Short-term heat resistance : 180°C

Maximum short-term heat resistance up to 60sec.: 250°C

Long-term heat resistance : 120°C degrees Celsius High temperature curing

Material: TORAYCA™ fabric - carbon fiber cloth

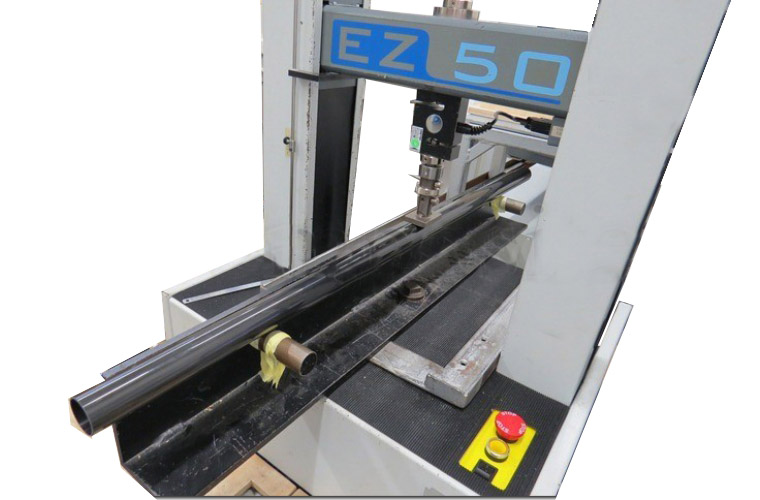

Process of production:

Tube - Roll/Twill Wrapping

Plate - TWILL OVERWRAP

Resin: Epoxy Resin

Regular Dimension Tolerance: +/-0.1mm

Deviation

Tube DiamaterIternal permitted deviation (mm) |

|||||||||

ID - Inner Diameter Range (mm) |

OD - Outer Diameter Range (mm) |

Length (mm) |

|||||||

|

Tube Dimension (mm) |

2 - 5 |

6 - 30 |

30 - 100 |

100 - 300 |

3 - 30 |

30 - 100 |

100 -300 |

Under 2000 |

Over 2000 |

|

Regular Tolerance (mm) + |

0.15 |

0.05 |

0.08 |

0.2 |

0.05 |

0.08 |

0.2 |

0.5 |

2 |

|

Regular Tolerance (mm) - |

0.05 |

0.05 |

0.05 |

0.1 |

0.15 |

0.15 |

0.2 |

0.5 |

2 |

Material - CARBON FIBER

Torayca® T300 DATA SHEET |

||||||

FIBER PROPERTIES |

||||||

|

English |

Metric |

Test Method |

||||

|

Tensile Strength |

512 |

ksi |

3,53 |

MPa |

TY-030B-01 |

|

|

Tensile Modulus |

33.4 |

Msi |

230 |

GPa |

TY-030B-01 |

|

|

Strain, elongration |

1.5 |

% |

1.5 |

% |

TY-030B-01 |

|

|

Density |

0.064 |

lbs/in 3 |

1.76 |

g/cm 3 |

TY-030B-02 |

|

|

Filament diameter |

2.8E-04 |

in. |

7 |

μm |

||

Material - 3K, 2 x 2 Twill Weave Carbon Fiber Fabric

FUNCTIONAL PROPERTIES 3K Carbon fiber |

||

|

Fiber Unit |

3K |

|

|

Yield, Tex |

198 g/1000m TY-030B-03 |

|

|

Yield, Tex (UK) |

7,523 ft/lbs |

|

|

Number of filament |

3000 |

|

|

CTE |

-0.41 α⋅10 -6 / ̊C |

|

|

Specific Heat |

0.19 Cal/g⋅ ̊C |

|

|

Thermal Conductivity |

0.025 Cal/cm⋅s⋅ ̊C |

|

|

Electric Resistivity |

1.7 x 10 -3 Ω⋅cm |

|

|

Composition Carbon |

93 % |

|

|

Fiber Unit Yield, Tex |

3K |

|

|

Tensile Strength |

0.19 Cal/g⋅ ̊C |

|

Material - COMPOSITE

COMPOSITE PROPERTIES* |

||||

|

Tensile Strength |

270 ksi |

1,86 MPa |

ASTM |

D-3039 |

|

Tensile Modulus |

20.0 Msi |

135 GPa |

ASTM |

D-3039 |

|

Tensile Strain |

1.3 % |

1.3 % |

ASTM |

D-3039 |

|

Compressive Strength |

215 ksi |

1,47 MPa |

ASTM |

D-695 |

|

Flexural Strength |

260 ksi |

1,81 MPa |

ASTM |

D-790 |

|

Flexural Modulus |

18.0 Msi |

125 GPa |

ASTM |

D-790 |

|

ILSS |

14 ksi |

10 kgf/mm 2 |

ASTM |

D-2344 |

|

90 ̊ Tensile Strength |

11.0 ksi |

76 MPa |

ASTM |

D-3039 |

Toray 250˚F Epoxy Resin. Normalized to 60% fiber volume. |

||||